Search

Press releases

11th March 2024

CHANGE IN THE MANAGEMENT OF THE CHIRON GROUP

29th September 2023

The CHIRON Group at the EMO Hannover 2023: A brand of its very own

19th September 2023

SUSTAINABILITY by Performance and Precision: CHIRON Group publishes its Sustainability Report 2022

4th August 2023

CHIRON Group at the EMO Hannover 2023 – experience innovations live

15th May 2023

Future-oriented manufacturing processes in focus

10th May 2023

Gaining a competitive edge – in all industries

10th May 2023

CHIRON Group continues to grow

11th April 2023

CHIRON Group management team complete

16th March 2023

The CHIRON Group invites to the OPEN HOUSE 2023

23rd December 2022

SUSTAINABILITY by Performance and Precision: The CHIRON Group publishes its first sustainability report

28th October 2022

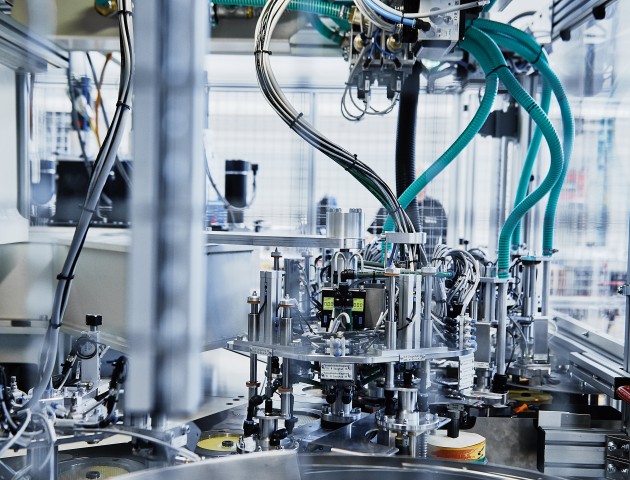

AM Coating: Innovative coatings for brake disks

21st September 2022

The chips are flying again: The CHIRON Group at the AMB 2022

19th September 2022

Machining centers now available with new Siemens SINUMERIK ONE control system

1st August 2022

The CHIRON Group acquires spindle and fixture specialist in Croatia

25th July 2022

CHIRON Group at the AMB 2022: Innovations in action and all-round expertise

31st May 2022

Thanks and appreciation

30th May 2022

Repair, don't make new! With automated LMD

16th May 2022

Combined expertise for the future: At the CHIRON Group OPEN HOUSE

11th May 2022

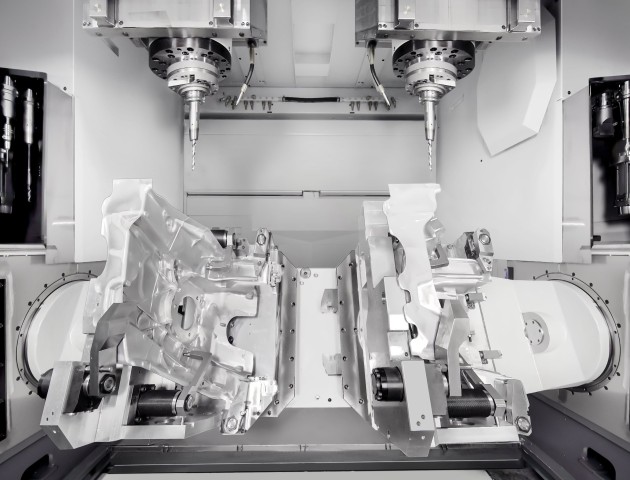

Product innovations with and for the future

11th May 2022

Sustainable thinking – innovative action

11th May 2022

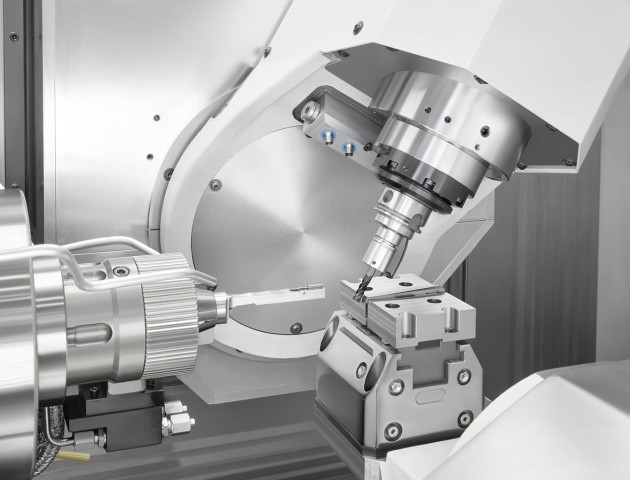

Competences combined, complete machining expanded

11th May 2022

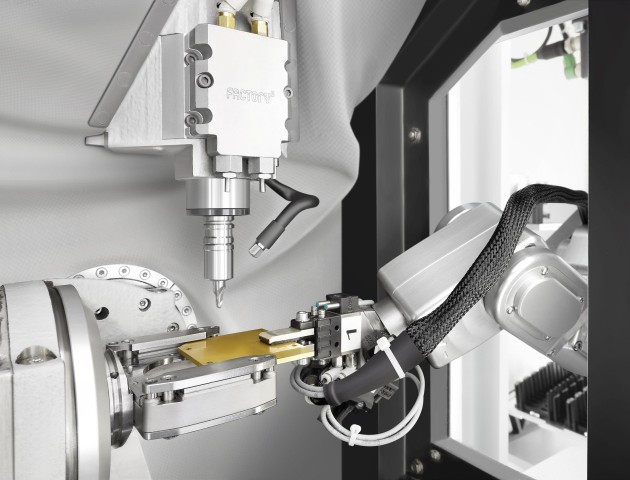

Smart cooperation for networked manufacturing

23rd March 2022

A next-level experience: the CHIRON Group OPEN HOUSE 2022

13th January 2022

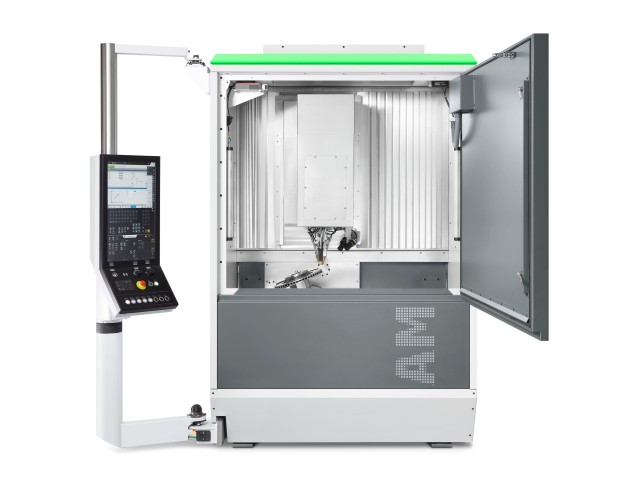

CHIRON Group and Greidenweis combine automation expertise