Search

18 Series

Compact, powerful, fast: The 18 Series single and double spindle machining centers offer the ideal conditions for highly productive machining and precise results. Whether it's for flexible single-part production or for small and medium-sized Series production, tried-and-tested modules can be individually configured to suit your production needs in the Automobile, Aerospace or Mechanical Engineering industries.

With a fast basket tool changer, rigid table, and large working area, the FZ 18 S is suitable for universal use. For flexible machining of rims in sizes of 16 to 24 inches, a special wheel variant is also available. You can manufacture large quantities productively with the FZ/DZ 18 W machining centers with automated tool and workpiece changers.

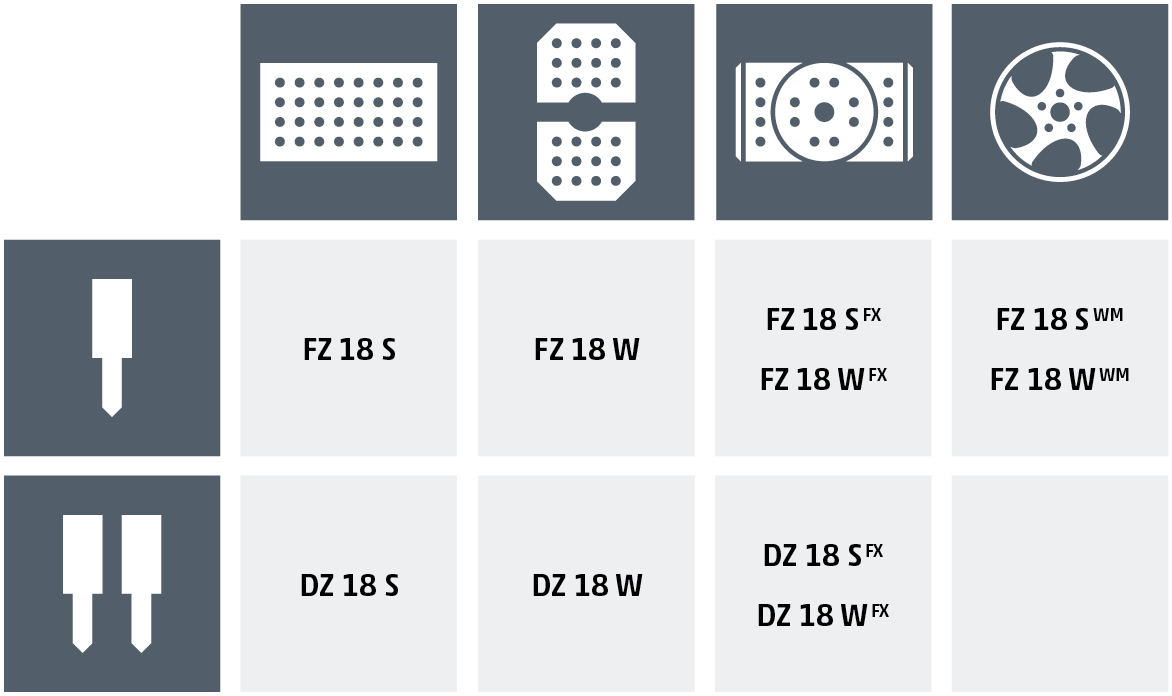

Machine variants

Highlights

Reliably strong performance in long-term operation

Compact machine layout

Flexible wheel device

Vertical traveling column

Mineral casting machine bed

High rigidity and thermal stability

Dynamic direct drives and precision guides

High running, positioning, and long-term precision

Robust rotary axes

Fully enclosed working area, stainless steel covers

Ideal chip flow directly into the chip feeder

Ergonomic operating and loading concept

Easy access to all units for servicing

»Precise, powerful machining. Compact, with cutting edge technology.«

Example applications

Contact