Services

PERFORMANCE MEETS PRECISION: This is the promise that the CHIRON Group makes when they deliver every machining center as well as Automation solutions and Refurbishments. An integral part of this commitment is the highly efficient CHIRON Group Service with over 500 service professionals in 26 countries. With »classic« on-site services and reliable partners, they will support you throughout the entire lifecycle of your machine.

LifetimeSolutions: The right services at the right time

Today, professional CHIRON Group Service is more – it is looking ahead, planning ahead, and thinking ahead. This is exactly what the LifetimeSolutions will ensure: A targeted response throughout the entire lifecycle of the machine. Using a completely customized package with the ideal support and digital SmartServices to suit the machine, the production environment, and the respective requirements. And clear added value: Greater productivity, maximum machine availability, and therefore, optimized overall equipment effectiveness.

Performance up, cost down – in every phase

Start-up, production and modernization: With LifetimeSolutions you will receive comprehensive, targeted support in every phase. The service specialists ensure that the start-up phase is short, and a high machine availability is achieved as soon as possible. Then, it is a matter of securing this high level, identifying, and exploiting additional potential. In phase three, your machining center undergoes targeted modernization and is ready for a second life with new tasks.

Always here for you: Service Hotline 24/7

+49 (0) 7461/940-5555

[email protected]

Expertise: complete

Fault management, maintenance, repairs, original spare parts, modernization, and training: the CHIRON Group Service offers the full spectrum. And the advantage: personal advice and support from specialists with sound technical training and plenty of experience.

Fault management

Ideally, rectify fault messages quickly and directly, provide support with troubleshooting by telephone and remote diagnosis with a real-time view of the machine's control system.

Maintenance and repairs

An individual service agreement for maintenance and repairs minimizes unplanned machine downtimes, maintenance costs. Dates can be planned, and the availability of the machining center is ensured.

Repair service

A professional repair brings core components such as the main spindles and motorspindles, swivel axles, or rotary tables back to optimum condition – with a manufacturer guarantee, of course.

Original spare parts

Tailor-made, available quickly, with performance guaranteed: original spare parts for optimum operation. Fast and reliable delivery from the central warehouses in Germany, China, and the USA, to you.

Optimization

The CHIRON Group’s service technicians are familiar with all process and product innovations from the company, and know the adjusting screws that will make your process quicker, more dynamic, and more stable.

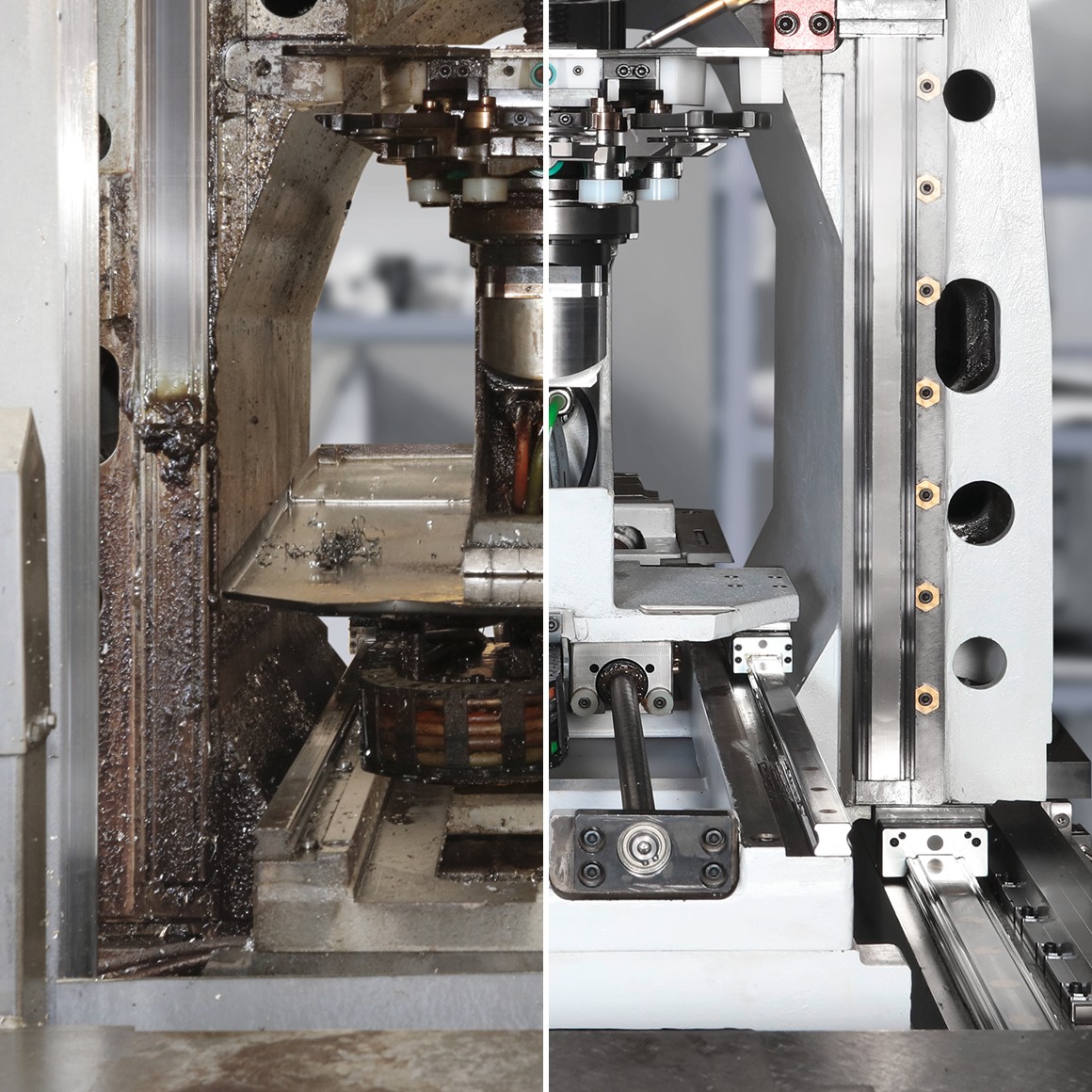

Modernization

Do you need to adapt manufacturing processes to current or new customer specifications, or improve quality and performance? These requirements can be fulfilled quickly and cost-efficiently with a retrofit, a partial or complete refurbishment.

Training

To help you use the full potential of your machining center, we offer a comprehensive range of training and qualification courses at our training center, or at your site.

Service request