A success story

Automotive, Medical Technology, Aerospace, Precision Technology, Tool Manufacturing, Mechanical Engineering: The CHIRON Group machining centers ensure precise, productive, and flexible machining in these industries. This expertise is no accident, but the result of continuity in mechanical engineering, and a strong change in technology and product range.

Change is the formative principle; it is the common thread that has continued to run through the company since 1921 and is firmly woven into the DNA of the CHIRON Group. The company has been willing to change to meet the demands of the customers and markets, to quickly recognize potential, and to systematically exploit it.

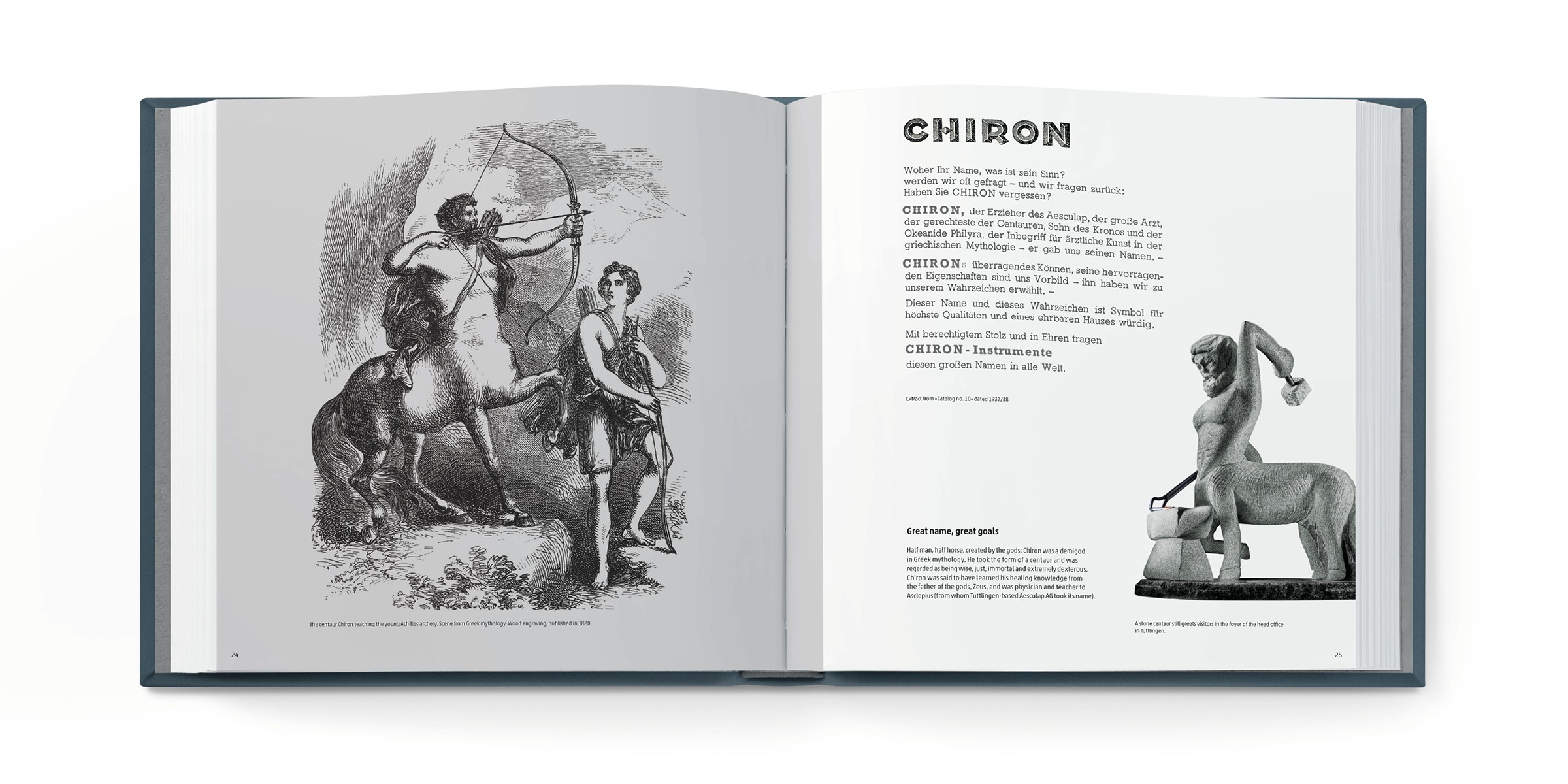

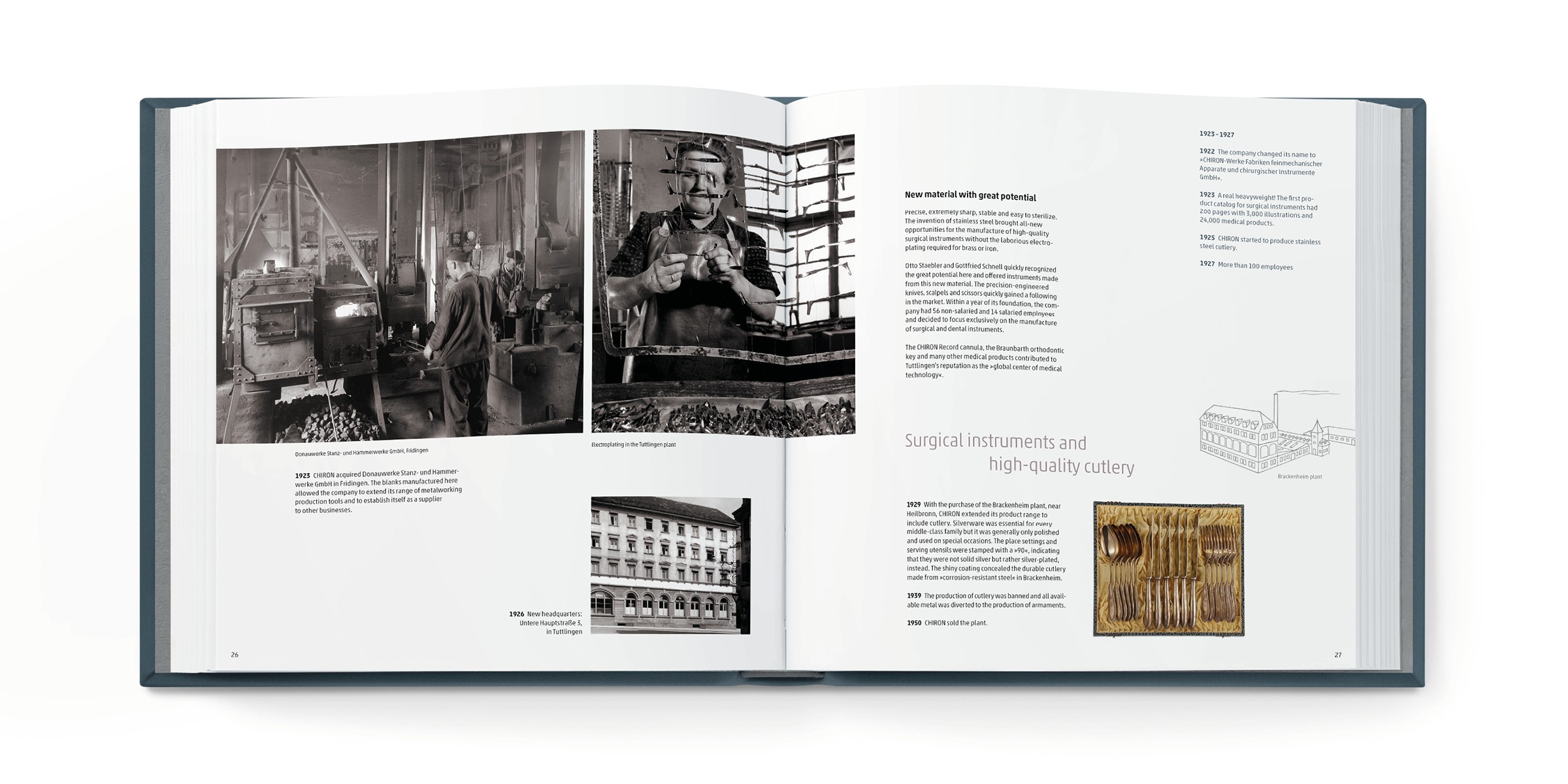

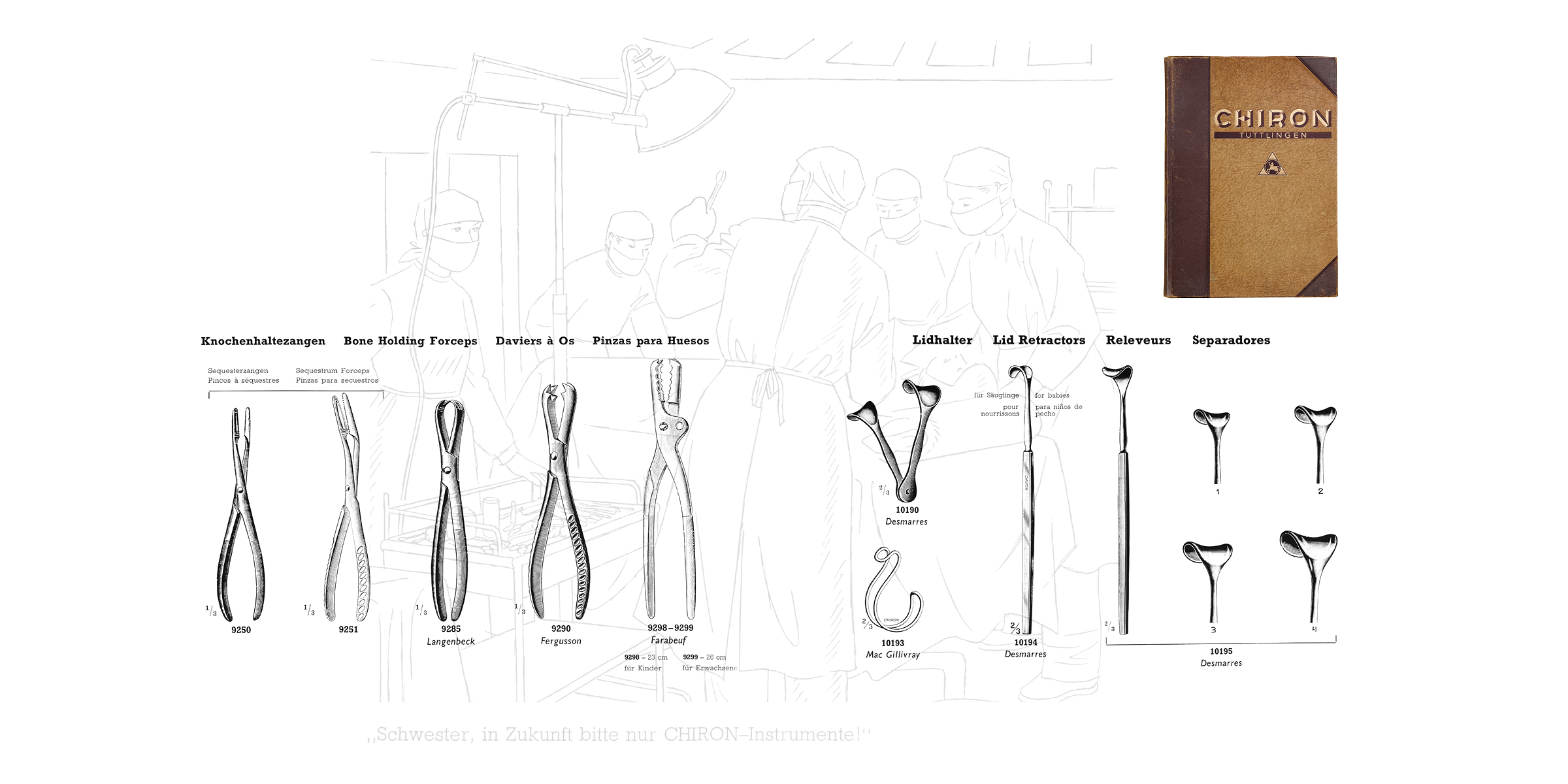

Where it all began: Surgical equipment

The foundation of the »Fabriken für feinmechanische Apparate und chirurgische Instrumente GmbH« – a precision appliance and surgical instrument manufacturing company, by Otto Staebler and Gottfried Schnell in 1921, was made possible by the invention of »stainless steel« in 1912. The two founders were quick to recognize the huge potential of this revolutionary material, and went on to produce new, innovative instruments: precise, extremely sharp, stable, and easy to sterilize. By the end of the 1930s, the product range was already comprised of around 30,000 medical technology products. CHIRON, together with other companies, established Tuttlingen's reputation as the »global center of medical technology«.

Compressors: CHIRON guarantees safe air

The compressed air industry began in the early 1950s. CHIRON recognized there was significant potential in compressors and pressurized-air devices and systematically developed the new market. Soon, the product range expanded from compressors for installation to stationary compressor systems for a wide range of markets. High performance, compact design, and easy access are just some of the compressors' advantages that are characteristic of CHIRON and continue to make the CHIRON Group machining centers stand out from the competition to this day.

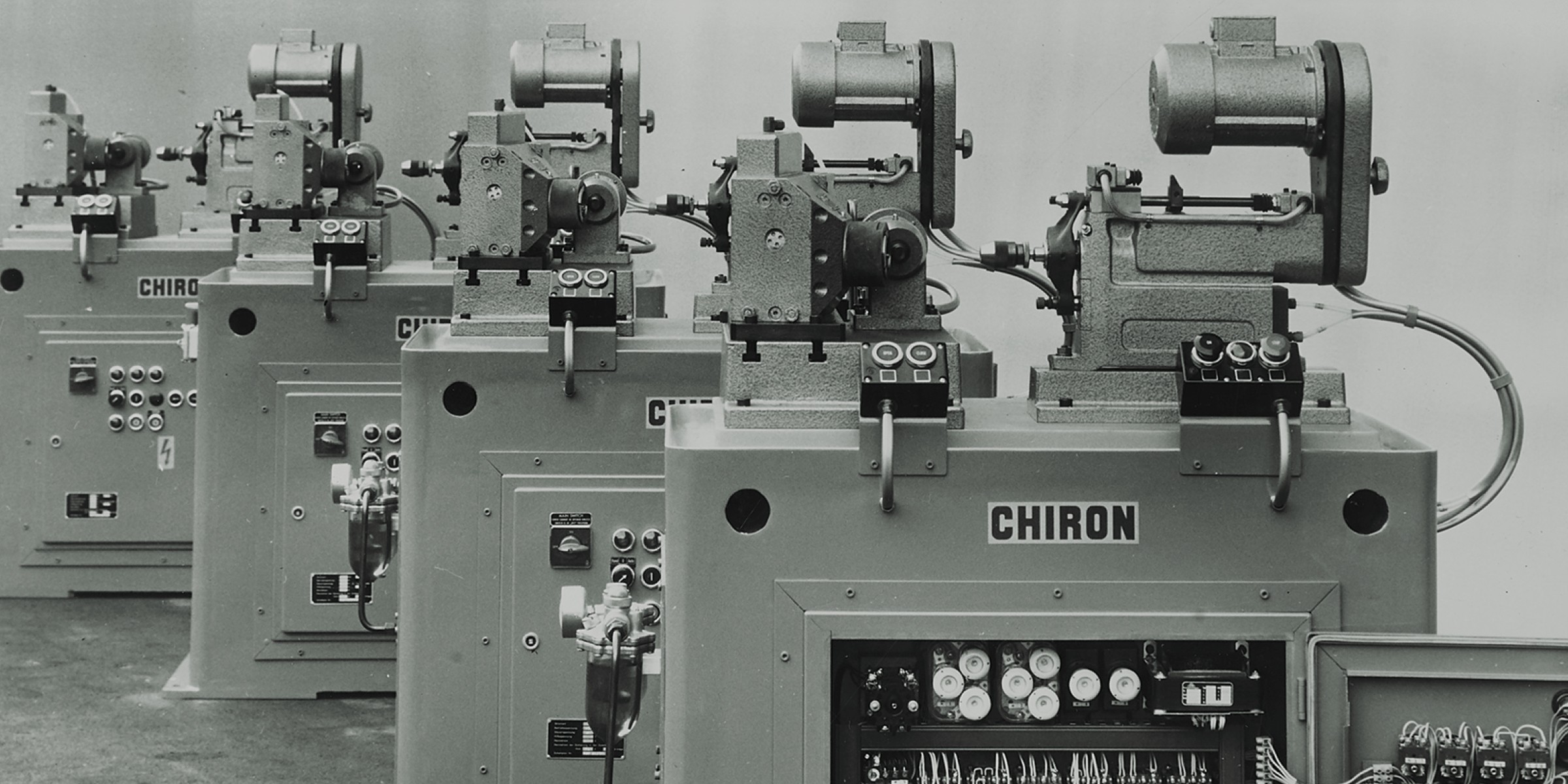

New perspective: Machining centers

CHIRON presented its first feed units for metalworking as early as 1958, and then further developed these units into specialized machines for machining processes. Based on its knowledge of the specific requirements for customers, the company created the perfect, individually-tailored solution: Machine components, mechanisms, workbenches, and tools were adjusted so that high volumes could be manufactured precisely and efficiently. You could say that these individual machining units mark the beginning of the turnkey competence of CHIRON, and now, the CHIRON Group.

A success story with longevity

With its innovative products and services, the CHIRON Group now facilitates precise, productive, and flexible machining in many different industries. Together, all employees are pursuing one goal: Remaining the benchmark for quality, technology, and service for all customers around the world and building on their advantage. One thing remains as important for future positive development as it ever has been: The passion for precision.