CHIRON Group at the AMB 2022: Innovations in action and all-round expertise

25th July 2022

PERFORMANCE MEETS PRECISION: The new claim from the CHIRON Group is also a promise, which will be fulfilled in all areas of expertise in Hall 10, Booth A41 of the AMB 2022 from September 13th to 17th, 2022, with the special combination of performance and precision in products, solutions and services. For sustainably productive processes in all industries.

Milling and Mill-turning, Additive Manufacturing, Automation, Turnkey, Digital Solutions, Services, Refurbishment: Over the five-day event, visitors can get to know the extensive portfolio, gain in-depth information on the topics that matter most and hear advice from the experts.

Machine highlights live in action

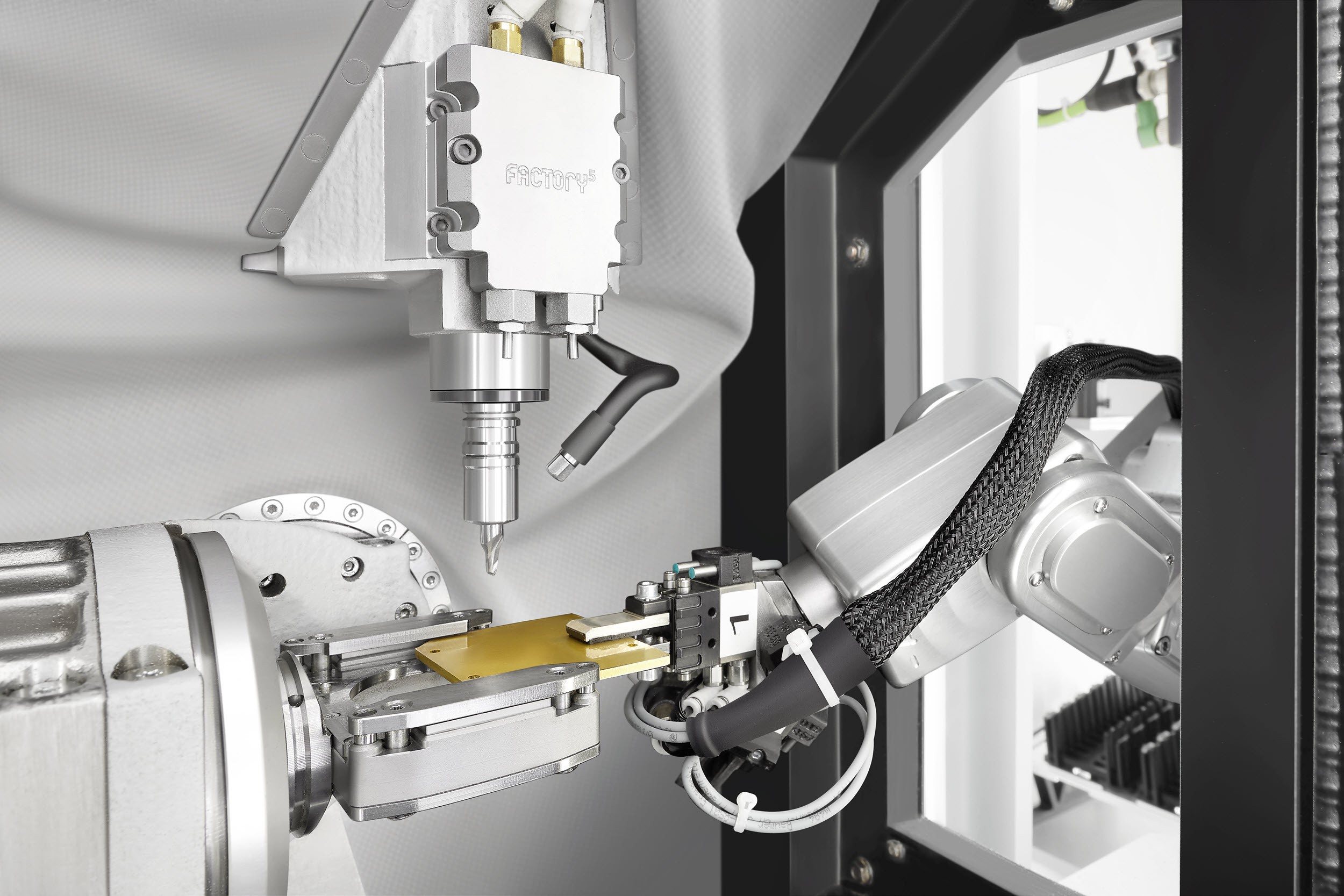

The CHIRON Group will showcase its expertise in the fields of milling and mill-turning with live-action demos of three innovative machining centers: The DZ 22 W five axis efficiency booster with HSK-A 100 interface and spindle distance of 600 mm for the machining of complex components for the automotive and aerospace industries. An ultra-compact plug-and-play solution consisting of the Micro5 machining center with the Feed5 handling system for automated, high-precise micromachining. And the new MT 715 two+ with integrated workpiece handling for multifunctional complete machining from the bar – also in unmanned shifts.

A special kind of cinema experience

To see other highly productive machining centers in action, it is also worth visiting the „CHIRON Group cinema“, which will be showing live broadcasts from Tuttlingen, Germany, twice a day. Or take a look in the interactive showroom, where you can see the STAMA 733 Series for heavy mill-turning and drilling operations as well as 5-axis simultaneous machining.

Best performance in all disciplines

Speak in person with the experts at the exhibition booth to find out all about other areas of expertise, such as Additive Manufacturing, Automation, Turnkey, Digital Solutions, Services and Refurbishment. In the Additive Manufacturing area, you can find out about the smart generation of laser metal deposition with the 3D metal printer AM Cube. And, in an exclusive preview, visitors get a sneak peek on the latest innovation – AM Coating. This industrial system applies anti-corrosion and wear-resistant coatings to brake disks, for hybrid or electric cars, for example.

The CHIRON Group will be presenting tomorrow's production, today, in the form of the digital systems of the SmartLine software portfolio. How smart and intelligent are the ProtectLine and ConditionLine modules in practice, for example? The experts, together with two cooperation partners, will be demonstrating this on the DZ 22 W five axis double spindle machining center. Visitors will be able to see the actual added value offered by automated tool handling with ZOLLER and coolant management with MOTOREX.

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, Germany is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey and automation solutions. Comprehensive services, digital solutions and products for additive manufacturing complete the portfolio. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries, as well as tool manufacturing.

The CHIRON Group is proprietor of the CHIRON, STAMA and FACTORY5 brands for new machines, as well as the automation brand GREIDENWEIS and the retrofit brand CMS. CHIRON's machining centers are renowned for their highly dynamic design and their precision. STAMA's focus is on stability and complete machining, while FACTORY5's expert area is high-speed machining of micro-technical components. GREIDENWEIS is a system partner for custom, end-to-end automation solutions, and CMS provides completely overhauled machines from the Group. The final core area of expertise in the CHIRON Group is in additive manufacturing products and solutions.

Contact person for editors:

CHIRON Group SE

Christina Messmer

Kreuzstraße 75, 78532 Tuttlingen, Germany

Phone: +49 7461 940-3712

Mail: [email protected]