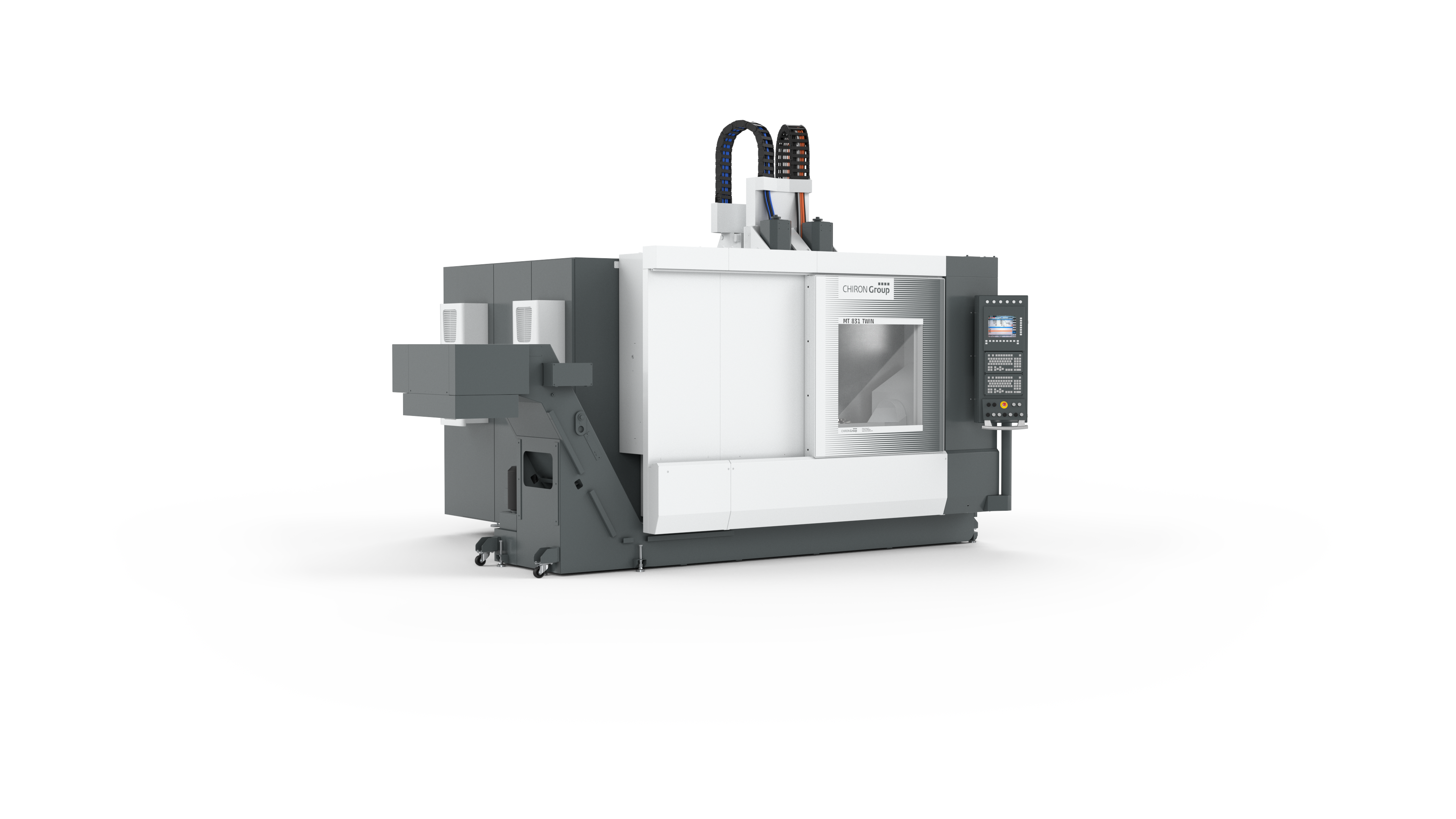

831 Series

Do you need complete machining of complex, precise workpieces with a diameter up to 400 mm, single or double spindle, 5-axis from chuck parts, whether it is a prototype, pilot series, or volume production? The right solution is the mill-turn centers of the 831 Series for full capacity in milling and turning with high dynamics and precision, in one machine.

Milling, turning, and drilling operations can be combined into any sequence to create the optimum machining process. This is a great benefit, when geometric form and positional tolerances of a subsequent machining step have to be realized with high precision in relation to a given reference. High surface area productivity and fast set-up and changeover are further plus points.

Machine variants

Highlights

Precise 5-axis complete machining from chuck parts

Made for large workpieces and multiple clamping

High process reliability

Individual process sequence design

High surface area productivity with MT 831 TWIN

Reduced costs per unit

Full turning spindles in the C-axis

Full milling and turning capacity in HSK-A63

Torque technology in the A-axis

Manual or automated workpiece handling

»Complete milling and turning. From prototypes through pilot series to volume production.«

Example applications

Contact