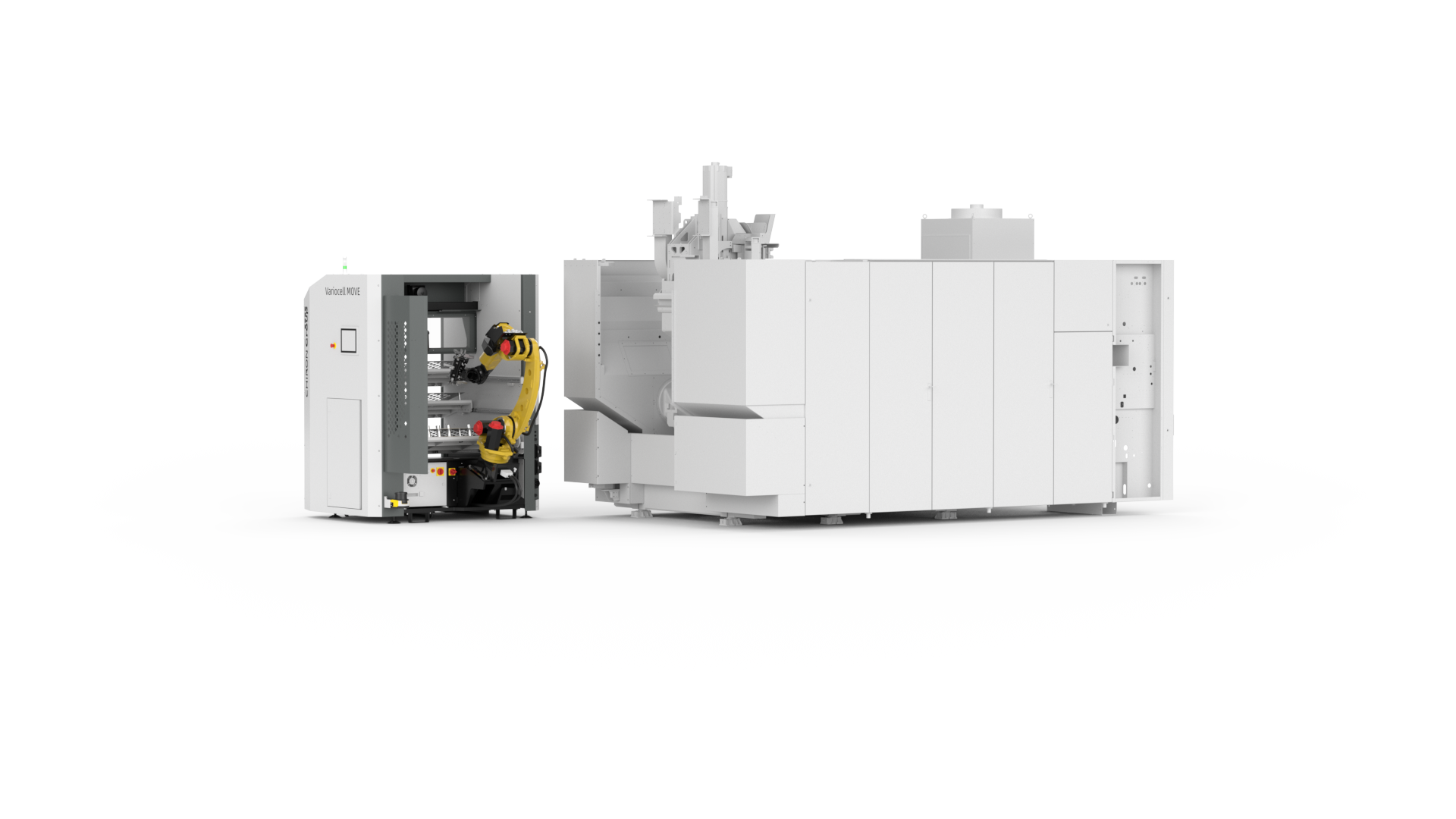

Variocell MOVE

Higher machine uptime, increased efficiency, reduced unit costs, less strain on operators: With the Variocell MOVE, you can achieve these benefits wherever they are currently needed. The compact robotic cell with inclined pallet system for intelligent workpiece handling can be flexibly combined with changing milling and mill-turning centers from the CHIRON Group into a highly productive unit.

Depending on the application, additional stations can be integrated, e.g. for turning the workpieces. Laser scanners create graded protective areas around the Variocell MOVE. When operators approach, the speed is reduced (level 1) or the system is shut down (level 2).

Highlights

Handling system for the 12, 15, 16, 18, MILL and baseline Series

High degree of utilization for increased profitability

Compact unit with a small footprint

Flexible and easy set-up

Intuitive operating and programming

High operating safety thanks to laser-scanned protective zones

Smart workpiece handling and fast pallet exchange

Robot reach up to 2,000 mm

Handling capacity up to 15 kg

Loading capacity per drawer max. 300 kg

Drawer size 1,100 x 570 mm

Workpieces up to 250 mm height / diameter

Optional gripper unit for prismatic workpieces

Robot FANUC M-20iD/35

Machining center and automation from a single source

»Automation flexible and on demand – at changing machining centers«

Contact