Product innovations with and for the future

11th May 2022

Combined friction stir welding and machining processes, scalable manufacturing system for microtechnology, high-productivity twin-spindle machining – three new product innovations by the CHIRON Group, focusing on productivity, efficiency and sustainability.

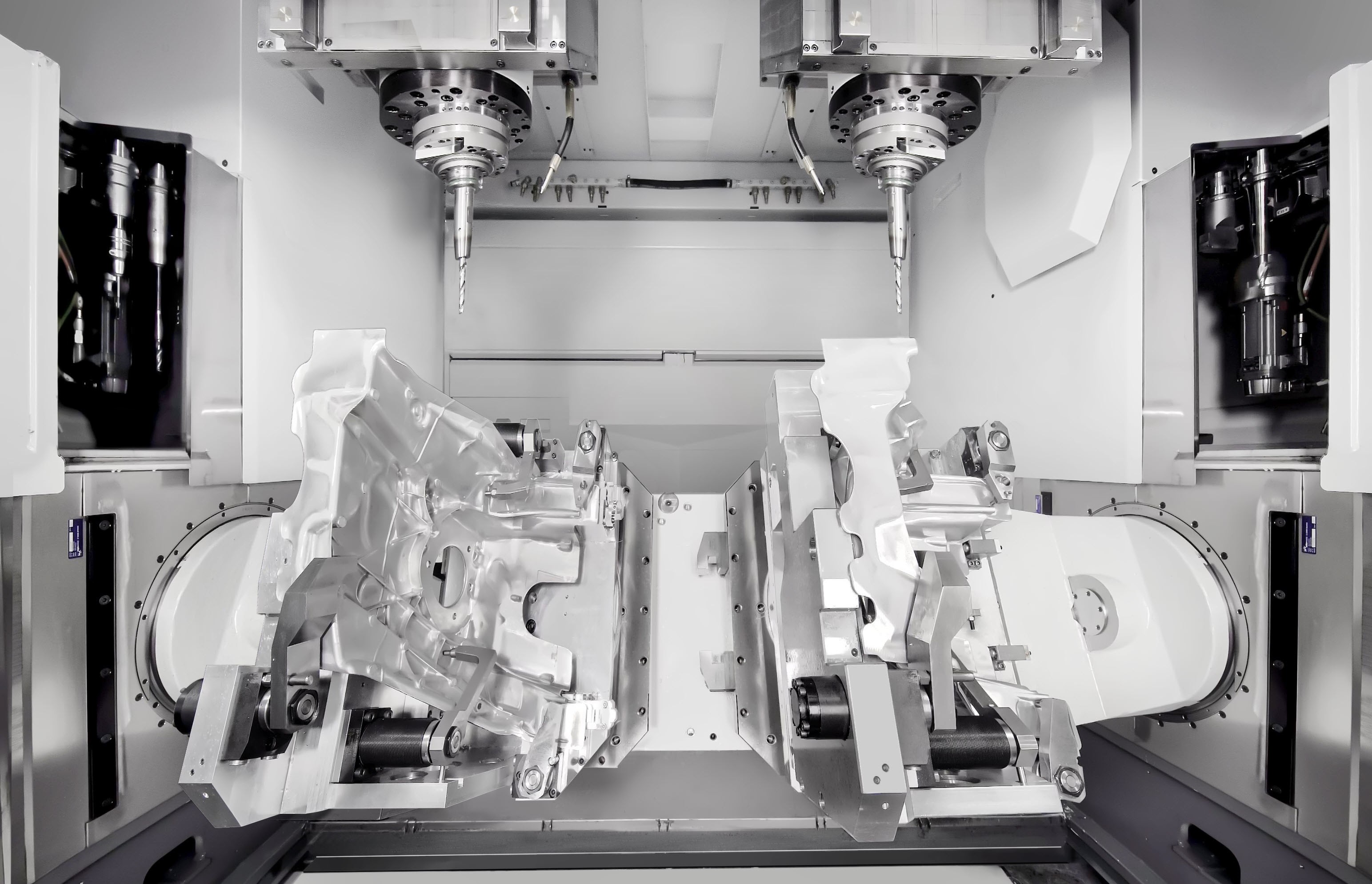

High dynamics plus high stability plus large working chamber plus twin-spindle concept with a spindle distance of up to 1,200 mm: The 22, 25 and 28 Series from the CHIRON Group are primed to set a new benchmark in terms of productivity and precision in this size – and are demonstrably doing so already. As an example in practice, a DZ 25 P that has been in use for two years is setting a new benchmark in manufacturing structural components for the automotive industry. All in all, this turnkey solution has provided, according to the customer: „A stable and high-precision process with greatly increased output in comparison to the previous system."

In addition to other double-spindle applications such as battery and e-motor housing manufacturing, these new series are also fully capable of massive machining applications starting with solid blocks. The extremely stable portal design forms the basis for high precision, while well thought-out working area and user ergonomics enable flexible integration of a wide range of automation solutions for ideal productivity and process reliability.

Sustainable machining of prototypes and series – with the scalable manufacturing system

The CHIRON Group is offering a groundbreaking manufacturing system for the microtechnology sector, for high-precision automated machining of workpieces with maximum dimensions of 50 x 50 x 50 mm. It is based on the Micro5 from the FACTORY5 brand – a high-speed milling center with the power consumption of a coffee machine and the size of a refrigerator. As a stand-alone solution, it is ideal for manufacturing smaller batch sizes in the medical technology sector, in the watchmaking and jewelery industry and in precision engineering applications. Thanks to its six-pallet capacity, the Micro5 also supports production with minimal personnel.

The combination of a Micro5 with a Feed5 handling system will form an ideal plug-and-play solution once it enters series production. Feed5 offers increased autonomy for automated workpiece handling with a six-axis robot. Capacities for Micro5 and Feed5 projects are currently being expanded further.

Combining FSW and machining – new innovation for sustainable mobility

One process that may not be particularly well known is Friction Stir Welding (FSW), a reliable, efficient, and sustainable manufacturing technology for creating pressure-tight and media-tight connections between two materials. FSW is fundamentally suitable for applications involving joining aluminum or unrelated materials. The target workpieces for FSW currently include, in particular, battery trays and inverter housings as well as all electronic components that require heat dissipation alongside high requirements for leak-tightness. Friction stir welding technology also enables car manufacturers to relocate electrical modules to the wet areas of vehicles.

The CHIRON Group boasts comprehensive expertise and practical user experience for machining these target workpieces. By combining FSW and machining, the CHIRON Group is developing a forward-thinking innovation to provide benefits for users similar to those offered by other process combinations: Reduced space requirements, shorter cycle times and higher quality and productivity. The first projects using this combination are already underway at a technology partner company, resulting in the first turnkey machining centers such as the MILL 2000 machining center, offering combined FSW and milling technology.

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, Germany is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey and automation solutions. Comprehensive services, digital solutions and products for additive manufacturing complete the portfolio. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries, as well as tool manufacturing.

The CHIRON Group is proprietor of the CHIRON, STAMA and FACTORY5 brands for new machines, as well as the automation brand GREIDENWEIS and the retrofit brand CMS. CHIRON's machining centers are renowned for their highly dynamic design and their precision. STAMA's focus is on stability and complete machining, while FACTORY5's expert area is high-speed machining of micro-technical components. GREIDENWEIS is a system partner for custom, end-to-end automation solutions, and CMS provides completely overhauled machines from the Group. The final core area of expertise in the CHIRON Group is in additive manufacturing products and solutions.

Contact person for editors:

CHIRON Group SE

Christina Messmer

Kreuzstraße 75, 78532 Tuttlingen, Germany

Phone: +49 7461 940-3712

Mail: [email protected]