Search

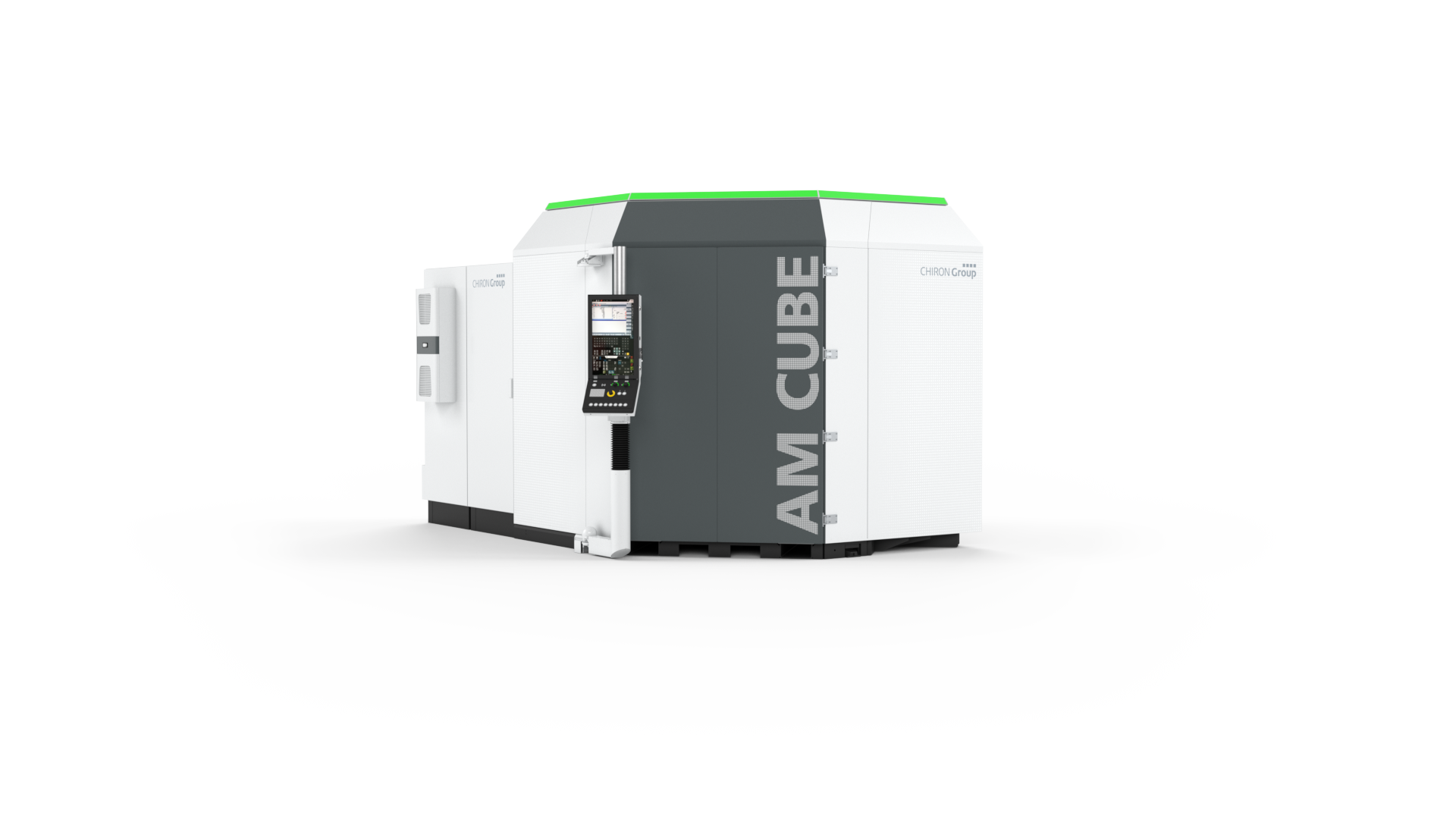

AM Cube

The AM Cube is a compact, user-friendly 3D metal printer for manufacturing large and complex components. It is suitable for coating and repairing components, as well as near net shape manufacturing of semi-finished products. It is possible to machine components with a diameter of up to 1,000 mm.

An innovative highlight of the AM Cube is the ability to change the deposition head while the process is running in order to fulfill various requirements. For example, high surface quality and high deposition rate or internal and external coating, combined into one workpiece, or the application of wire and powder in different stages of production.

Highlights

Flexible use for coating, repair or 3D printing

Automatic changeover of the deposition heads (up to three) while the process is running

Wire or powder feedstock material

Modular design: 3-axis, 4-axis or 5-axis

Innovative user interface with TouchLine

»Easy to use«, thanks to well-known control system components from Siemens

Programming in DIN ISO or CAM in a Cartesian coordinate system

Comprehensive process monitoring with DataLine AM and VisioLine AM

»Innovation from the CHIRON Group: Changing the deposition head while the process is running«

Example applications

Contact