Search

22 Series

The 22 Series convincingly addresses the current requirements on precision, dynamics and high technical availability in the complete machining of large-volume components such as electric motor and transmission housings, oil sumps and chassis components. The foundation for this is a machine platform with a mobile gantry design. This significantly increases rigidity for even more precise machining results.

Using the DZ 22 W five axis with workpiece changer and a spindle distance of 600 mm, two different main spindles can be operated, depending on the task at hand: the high-speed spindle for workpieces made from aluminum or aluminum alloys, and the high-torque spindle for hard-to-machine materials and large tools. The series also includes configurations for direct loading and a HSK-A100 interface.

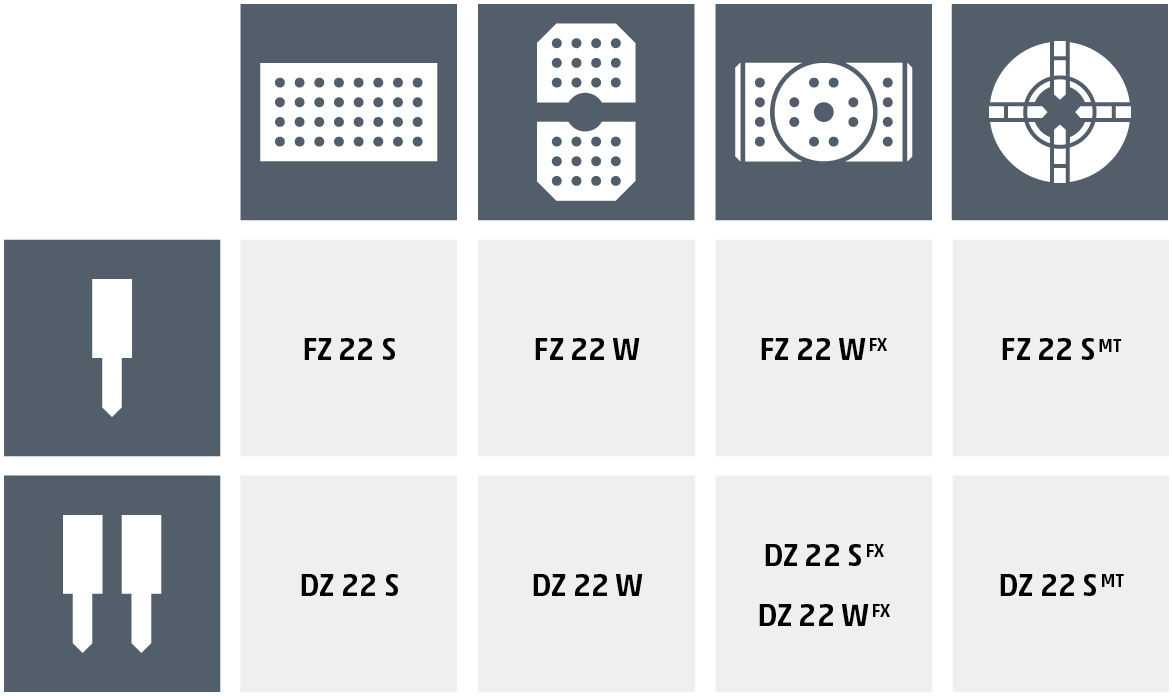

Machine variants

Highlights

Double spindle machining of large components in short cycle times

Rigid machine bed with a mobile gantry construction for high precision

Active cooling of all components

Compact, flexible machine layout

Many tools for versatile machining

Tool change during machine operation for maximum output

Process is easily visible thanks to the separation of operating and loading sides

Workpiece changer for loading and unloading during machine operation

Intuitive operation via TouchLine

Easy automation via robots or gantry

»Machining complex workpieces – precise, easy set-up, productive.«

Example applications

Contact